By inventing the silicone printing pad, TAMPOPRINT founded industrial pad printing. Our claim is to further develop pad printing technology at a high quality level with our innovations and to constantly increase performance and efficiency. With our pad printing machines, we ensure that TAMPOPRINT customers receive the best technology on the market and the ideal technology for their particular application, thus securing competitive advantages. Among other things, we have therefore further increased the degree of automation of our pad printing machines. We offer our customers in this area complex, full automations for large quantities and high cycle rates. These include the rotary automations CLOSURE PRINT COMPACT, ROTOPRINT or the modular system MAP (Modular Automation Platform). In applications where production flexibility and user-friendliness are particularly important, our semi-automatic systems of the MODULE-ONE Series score highly.

Our pad printing automations

MODULAR AUTOMATED SYSTEMS

MAP

Automation level

+++

Applications

Print/laser

Transport system

Rotary indexing plate

Working principle

Semi-automated

Components for integration

+++

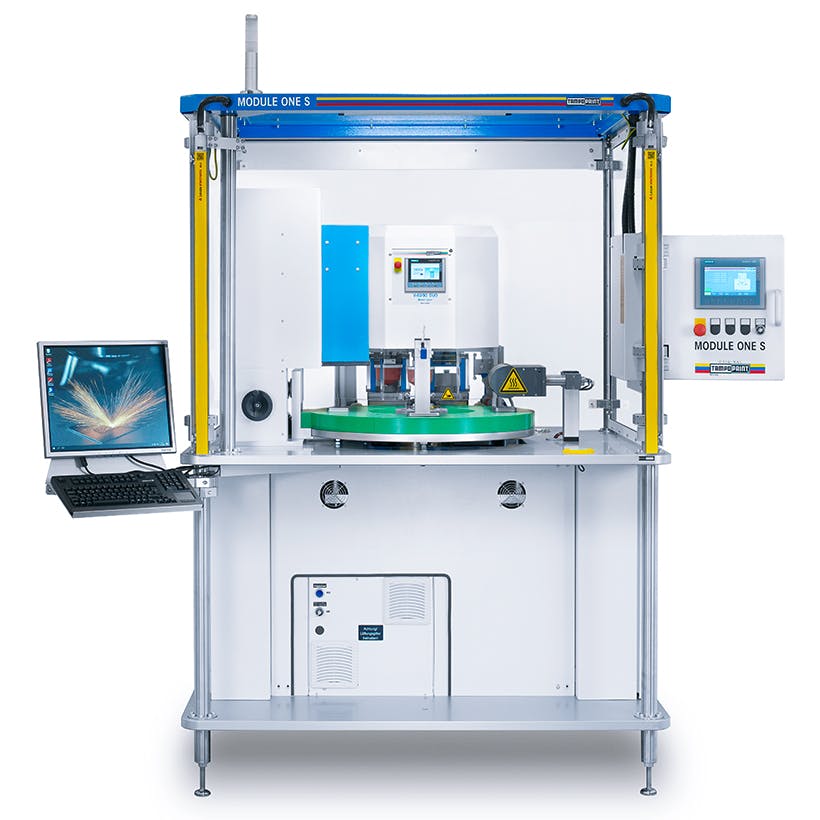

MODULE ONE S & M

Automation level

++

Applications

Print/laser

Transport system

Rotary indexing plate

Working principle

Semi-automated

Components for integration

++

ROTARY AUTOMATION SYSTEMS

CLOSURE PRINT COMPACT

Type

Caps

Printing unit

V-RTI 3000

Version

1-track

Number of colors

Max. 3 colors

Working principle

Continuous

ROTOPRINT

Type

Caps

Printing unit

H-RTI 21-150

Version

2- or 3-track

Number of colors

Max. 3 colors

Working principle

Continuous

Automation Services

Automation services

Our service staff will look after and support you with issues such as maintenance, retrofitting and repairs. They are there for you around the clock. Whether directly at your site or via remote maintenance and use of integrated remote assist technology.